|

Modntwia Import and export Co., LTD

|

punch press

| Price: | 1000.0~90000.0 USD |

| Payment Terms: | T/T,L/C;PAYPAL |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.High precision and Wide application

2.Little changing in mold height

3.Llow noise and Low energy consumption

4.Convenient processing though

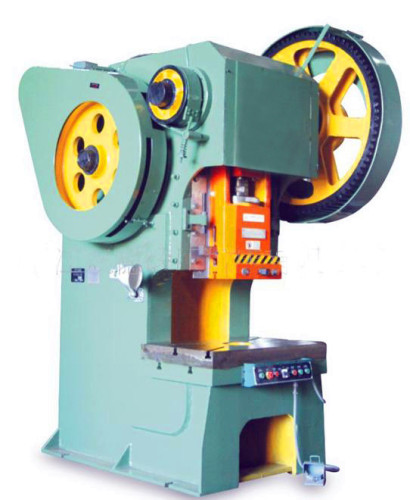

J23- series tiltable eccentric power press single crank c frame punching machine

Nameplate

Nameplate

Brand | WonLon | Type | Ordinary |

Model | J23-100 | Power type | Electric |

Voltage | 380v | Main power | 10kw |

Controller | Artificially | Layout | Vertical |

Throat | 290mm | Stroke length | 130mm |

Stem hole | σ60×75mm | Stroke rate | 50Spm |

Max shut | 480mm | Slid surface | 330,450mm |

Processing Obj. | Metal | Weight | 7500kg |

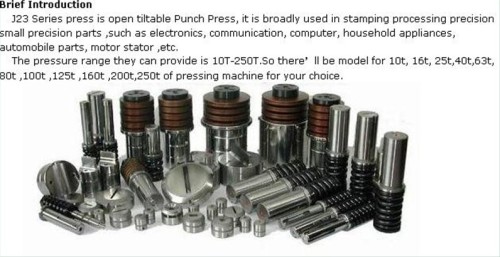

Brief Introduction

J23 Series press is open tiltable Punch Press, it is broadly used in stamping processing precision small precision parts ,such as electronics, communication, computer, household appliances, automobile parts, motor stator ,etc.

The pressure range they can provide is 10T-250T.So there'll be model for 10t, 16t, 25t,40t,63t, 80t ,100t ,125t ,160t ,200t,250t of pressing machine for your choice.

Application

A. Pressing and withdrawing axle and sleeve

B. Bending and shallow drawing sheet metal

C. Straightening, forming, cutting and punching various materials

D. Applied in compression trial.

E. External cover of computer and sheet metal parts

F. OA steel furniture drawer and rail parts

G.External cover of air conditioner ,and sth.liked.

Characters

1. Cast and inclinable frame, to ensure high rigidity and less deformation.

2. Turn-key and rigid clutch, flexible movement and reliable performance.

3. Crankshaft placed crosswise, V-type guides of the slide in high accuracy.

4. Press-collape block device, to ensure safety in press operation.

5. Emergency brake device, to control the slide stop any position within 135

if any occurrence such as the arms, any substances accessing in working area.

6.Photo electric protector, air cushion and other optional accessories can be equipped

with the power press according to the users denands.

Technical Parameter

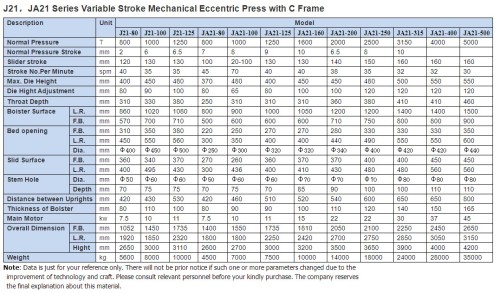

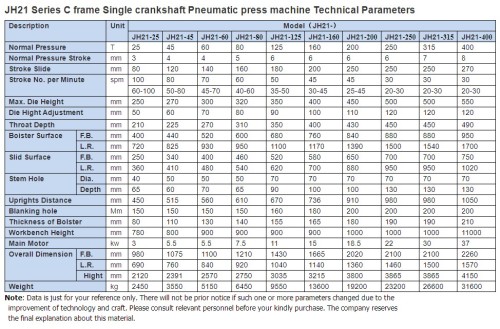

J21- series fixed worktable eccentric power press single crank c frame punching machine

J21 series press is regular open-die fixed platform press, it is the main equipment of stamping sheet metal production, and can be used for punching,blanking, trimming, bending, shallow or deep drawing,molding and various cold stamping process,and widely be used in national defense, aviation, automobiles, tractors, motor, electrical equipment, instrument, medical equipment, daily hardware Area, etc.The pressure range they can provide is 10T-350T.So there'll be model for 10t, 16t, 25t,40t,63t, 80t ,100t ,125t ,160t ,200t,250t,315t,400t ,500t of pressing machine for your choice.

Mechanical characteristics

Fram : The frame is of all steel construction, fabricated from Rolled steel plates with suitable cross ribbings. Presses upto 300T will be supplied with C.I. legs. proper alignment of the frame is ensured by machining.

Clutch : The clutchis of pin/rolling key-type. the clutch is rigid and well supported. the clutch gives continuous strokes for mass production

Crank Shaft : Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy

Flywheel : Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running

Gears : Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine

Table & Ram : Table and fam are made pf high grade heavy duty cast iron & properly seasoned. They are perfectly aligned, to each other to obtain high accuracy & precision press operation

Lubrication : An efficient shot luvrication system has been provided for lubricating the sliding surfaces and moving parts. The lubricant is applied by hand pump

Inclining : Inclinable type presses are provided with inclining mechanism which can be easily det and locked in

Mechanism : Position by spanners within minutes. the press ils so designed that even in maximum inclined position, it is stable under heavy pressing load

J21,JA21- series fixed worktable eccentric power press single crank c frame punching machine

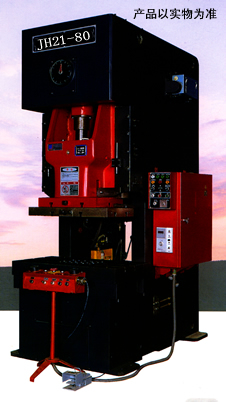

JH21- series fixed worktable Pneumatice ccentric power press single crank c frame punching machine

Performance characteristics

1. Adopting High quality steel welded fuselage, which all passed dispose by tempering (or vibratory stress relief) and shot blasting, which insure Good rigidity and high precision;

2. Longitudinal crankshaft, adopting grinding processing after high frequency quenching, insure compact structure and flexible rotation;

Extended six face Rectangular guide rail with bronze panels guide surface, guarantee high precision guiding;

3. Pneumatic double balance cylinder to balance the weight of the slider and the upper die, and to

eliminate clearance between the connecting rod and the slide block,which reduce impact ,abrasion and noise .

4.Centralized control by imported PLC system; gas circuit controlling by imported double safety valve ,

through which can realize the point move, inch move, single stroke or Continuous stroke;

5. Key workpiece such as The slider, guide rail , workbench, connecting rod, Link set, etc.are all manufactured by Resin sand craft,

compare with the clay sand craft,it can reduce the surface roughness 1-2 class,and improve the dimension precision 2-3 grade

6. Using electric outfit for die height adjustment on 60 T and above products; All configurate High-quality imported workpiece,

Ensure the overall excellent performance!

JH21 Pneumatic press technical parameters

Packing & Shipping

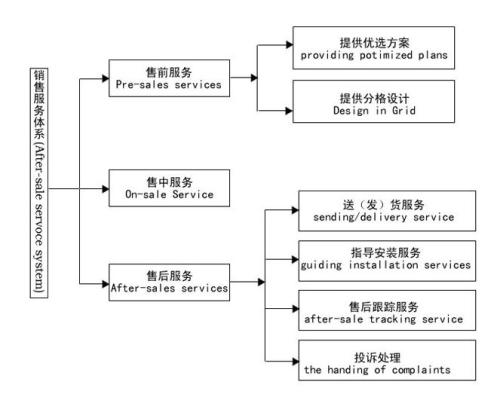

Service

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Punch Press Machine

Turret Punch Press

Single Punch Tablet Press

Single Punch Press

Punch Tablet Press

Punch Press Tools

More>>

.jpg)

.jpg)